Wildfire Ignitions Caused by Utility Circuits

Learn How Overhead Power Equipment Fails and Starts Fires

The problems in utility circuits that cause wildfire ignitions are relatively simple.

At a basic level, there are two ways these circuits start wildfires: overloads and arcing.

This article uses a few technical terms. Find definitions at the end of this article for: Fault, Conductor, Insulator, Jumper, Arcing, and Phase.

One often hears the term “sparking.” Sparking happens when a heated conductor gets so hot that it throws off small pieces of burning metal. Both overloads and arcing can throw sparks into dry vegetation where they ignite fires.

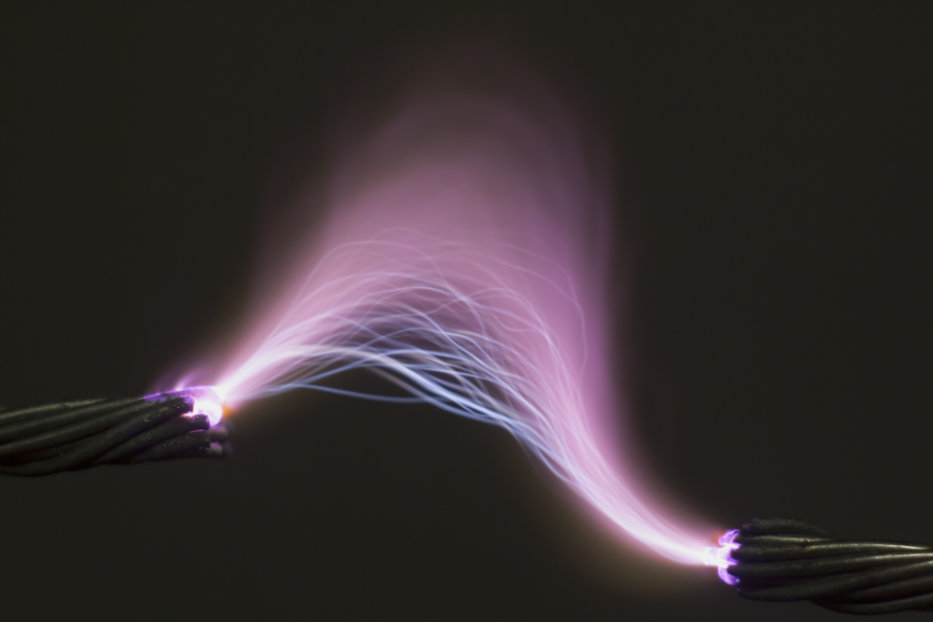

A characteristic of medium and high voltage electricity is its ability to arc through the air. The photo above shows a separated utility cable arcing. The higher the voltage (think of voltage as pressure) in an electric current, the further this arc will travel. The air is instantly heated into a plasma of gas ions (a corona discharge), that conducts the electricity.

This electric arc is very hot. See the molten metal on the left of this photo? These arcs and coronal discharges reach temperatures of thousands of degrees.

Photo of Transmission Tower Conductors Arcing

The tower in this photo is not owned by PG&E. But if you had been at the site of the Camp FIre ignition in Butte County CA, you may have seen a similar sight. There, a jumper cable fell into a steel lattice transmission tower when its old support hook broke. That tower was a line-transposition set up, where the jumpers cross places within the structure of the tower. According to the Butte County District Attorney, the broken hook was nearly 100 years old.

Jumpers are the cables in this snow landscape image that hang in a loop, conducting power from one side of this tower to the other. At transmission voltages (often 125,000 to 500,000 volts), out of phase conductors will arc through the air to each other, or to the structure. They need not make actual contact to create electrical faults. This is the reason high voltage insulators are so long. They must hold the power cables well away from these steel towers to prevent electricity from arcing to the grounded tower. All such support structures are inherently grounded and attract electricity.

Photo of a Power Overload

The photo on the left is of an overloaded circuit.

Too much current is flowing through a connection point that cannot handle the power without over-heating, burning, and throwing off pieces of molten metal.

This is not PG&E equipment.

Overloads happen when more current passes through a conductor than it’s designed to carry. In this fault, the wire/cable/bolt connection heats quickly and begins to burn. These faults also throw off molten metal. A fuse should have prevented the overload in this image.

You have felt an overload begin when the wire to an electrical appliance gets warm. Think of that wire to your electric space heater or toaster oven turned up high. It feels warm to the touch. This is the beginning of an overload. Bare primary conductor cables sometimes run hot, pushing more power through small conductors.

Downed Wires –– High Impedance Arc Faults

Below is a downed energized PG&E primary conductor wire causing a high impedance arc fault to earth. This can kill a person who gets too close and it can certainly cause a wildfire. This photo is from the Santa Cruz County. The wire is bare 6 gauge copper.

This fault can continue to arc for hours, or theoretically for days, because the earth is a poor conductor of electricity. Thus the current flow (amperage) involved is too low to trip (burn out) the utility fuses in the circuit.

There are other types of higher power arc and overload faults, such as line slaps between uninsulated cables. Line slaps are relatively common during high wind events.

Both problems are very dangerous. There is good equipment available to protect against these types of faults. These solutions were not employed.

Equipment Failures

Transformers on power poles can fail internally. Transformers lower the voltage from the primary conductors so that the electricity is safe to use connected to your house. Transformers can develop internal insulation failures that become very dangerous quickly.

Utility fuses and fused cut-outs are another potentially dangerous device. Fuses are intended as circuit protection and to fail sacrifically to protect other equipment and prevent fires. But certain fuses expel or drop molten metal when they function and so are fire ignition hazards themselves. Safe contained fuses are available but are not specifically required by CPUC code.

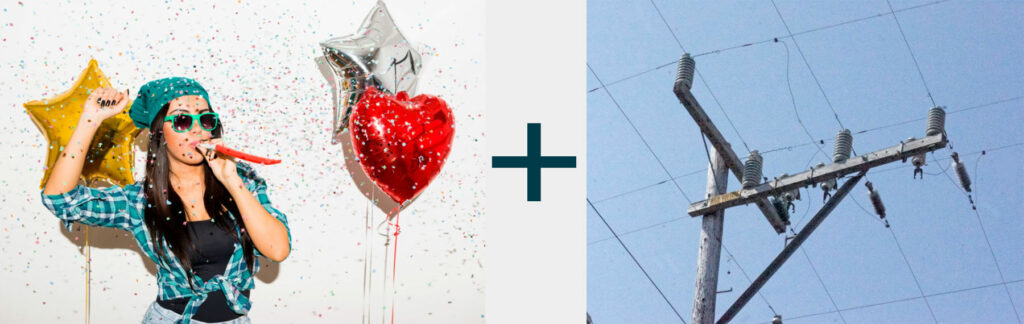

A Ridiculous Example that Demonstrates a Huge Safety Defect in Overhead Power Equipment

Party Balloons

Something as harmless as a Party Balloon is a big problem for overhead circuits because this equipment has been designed with uninsulated conductors

Mere latex, non-mylar party balloons drift into power poles and when they make contact between two phases, the result is a flashing arc fault.

High voltage electricity can also travel over the surface of non-conductive materials like wood and plastic. Most people are surprised by this, but it’s a common problem for uninsulated circuits. When this type of fault happens, the non-conductive material is heated and will burn.

The reason you always see ceramic insulators on power poles is to hold the conductors away from the grounded pole or tower. The ripple shape of the insulator increases the distance the power must travel over that ceramic surface to reach the cross bar and arc to ground. This distance prevents electrical arcing to the pole or tower. The higher the voltage in a circuit, the longer these insulators will be. High voltage Transmission Towers have very long insulators for this reason.

The images below are satirical, not literal.

Balloon contact arc faults are a common problem. PG&E reported that these balloons caused them 453 power outages in 2020. Southern California Edison (SCE) reported more. It’s a good idea to place a weight on these balloons so they can’t fly away and land in a power pole.

This fault can cause an explosive arc flash. Fires have resulted from these balloons landing in power lines. This problem can also cause power lines to fall. Insulated equipment would solve this problem, as well as solve numerous other types of dangerous electrical faults.

With full insulation of utility cable, jumper wires, clamps and contacts, these problems would vanish as would most of the wildfire ignitions that come from utility electrical faults.

This is an image of a PG&E 4,800 volt (estimated), two conductor power pole. This is a set-up in a rural PG&E location. Two circuits appear to be connected together on this pole – or this is a “corner pole” changing direction.

The small single strand wire used on this pole is bare copper. You can see the twisted wire connection on the ceramic insulator bolted to the steel cross bar.

Nothing is insulated except for the ripple shaped ceramic insulators that must be on every power pole. These ceramic insulators isolate electric power from burning the power pole and causing a phase to ground fault. The bare wire clamps and jumper connection wires are clearly visible.

If a cluster of party balloons landed in this pole, electrical arcing would be likely. Hopefully fuses would trip to prevent a wildfire, but this is not certain.

Below is a an equally dangerous power pole in an urban setting. See the street lamp? All of the primary conductor wire is small and uninsulated.

Only the wires leading down from the two transformers and out to buildings appear to be insulated. This pole is, in our opinion, dangerous. It is certain to be a hazard with mere party balloons.

Poles like this one are common in San Francisco – the home office town of Pacific Gas & Electric and of the California Public Utilities Commission. In a city, these old poles are often set in concrete and are difficult to replace.

High voltage electricity does not require conductive material contacts for an arc fault to occur. A large bird’s wings can conduct power between two phases that damages transformers or blows expulsion fuses, throwing molten metal to the ground.

Any non-conductive material, like a wind-blown fragment of plastic tarp, a small blown-in tree branch, or a squirrel that climbs a power pole, can conduct power between two out-of-phase bare cables, and jumper wires. Mere contact between that pole and a bare wire causes a fault.

To see videos of what happens when party balloons, or any debris, lands in uninsulated power lines, use the following internet search text:

“balloons exploding on power lines compilation”

Now you too have seen this dangerous bare wire electrical fault.

“Jumpers” are short sections of conductor that connect between main cables and transformers, fuses and other contacts on a power pole. PG&E has huge numbers of old, non-rigid, bare jumpers that move around in wind storms. Newer PG&E equipment we have seen uses stiff or rigid metal jumpers, but they were still uninsulated.

In years past, materials science had not yet developed sunlight-durable and heat-resistant insulation for power cables. Now there are common insulating materials like XLPE that last over 40 years in full sunlight and can make overhead power fire-safe and reliable.

Here are Types of Conductors PG&E has Continued to Use Despite Their High Risk Characteristics

This is a photo of the smallest overhead electrical conductor we have ever seen. This wire appears to be the same size used to wire one large kitchen range. We think this wire in the photo below is 8 gauge copper. It’s covered with some type of woven material upon which lichen is growing. This size of conductor is still allowed in California on 150 foot pole to pole spans.

This wire was photographed in Summer 2020. Sections were still in use, at that time, through a tall coast redwood forest in Santa Cruz County. Some had been replaced, which is how the photo below was taken, but other sections were overhead and connected. This area was burned in the CZU Lightning Complex Fire so this wire in that location may have been destroyed.

It remains legal to use this remarkably small wire as a primary conductor according to the CA Public Utilities Commission code General Order 95. This fact is, in our opinion, a scandalous issue for the Commission. Small cable/wire is cheap, period. There is no other reason to use it.

The Next Most Dangerous and Very Common Wire PG&E Uses is 6 Gauge or #6 Bare Copper

AWG #6 is larger in diameter than #8. But it is still only 0.16 inches in diameter.

We have measured this wire on 175 foot, pole to pole spans with repair splices. In 2013 a Liberty Consulting PG&E Rate Case report stated that PG&E had 22,000 circuit miles of this small wire in use across California. Liberty Consulting called this wire “obsolete” in their report to the CPUC. That report is available. Just contact us at the email address on the home page of this website.

This sample is burned from arcing to earth during a downed wire high impedance arc fault. Many thousands of circuit miles of this obsolete wire remain in use by PG&E, both in forests and on city streets. It often contains multiple repair splices that can fail when heated or stressed. PG&E took 2 hours to shut off the power after a 9/11 call reporting this downed wire in the photo.

TERMS IN THIS ARTICLE DEFINED

Fault is the term for any problem in an electrical circuit.

Conductor is the word for all electrical wires, cables and connections of any size or specific purpose that are used to convey electricity. Conductors can include pieces of metal and bolts. “Primary conductors” are the main power conductors in a distribution circuit.

Jumper refers to short sections of conductor that connect between transformers, fuses, switch gear, reclosers and the primary power conductors on a power pole. On transmission towers, the jumpers carry the power from one side of the tower to the other, connecting to the main cables before those cables attach to the ceramic insulators. These jumpers hang below outward extending arms to keep them away from the steel tower.

Insulators are ripple-shaped ceramic, glass, and polymer objects to which primary and secondary conductors are attached. Insulators come in many sizes and configurations. The purpose of insulators is to hold the main conductors and keep them far enough away from poles and towers to prevent electricity from arcing to that tower or pole. True high voltage transmission insulators are very long. Insulators are not the same thing as insulation covering a cable.

Arcing as used in this article, refers to the ability of electricity to travel through air and also over a non-conductive surface. Though in terms of physics, this surface conduction is called the “skin effect” which differs from plasma corona arcing. Arcing can be any distance from a fraction of a millimeter to several feet. An electrical arc can be thought of as similar to lightning, or to a welder’s arc.

Phase in Alternating Current or AC is the term for each of the three continuously pulsing flows of electricity in the three cables. In the USA, each phase reverses polarity from positive to negative 60 times a second. In European systems this happens 50 times a second. Each of the three conductors or phases in a utility polyphase circuit reverses polarity out of time sequence with each other. These phases are 120 degrees out of timing (360 degrees making a circle). A 120 volt house single phase circuit needs a neutral conductor to complete a circuit. But two or three phase power does not. This is why a 240 volt electric motor circuit does not actually require a neutral wire. A neutral and a ground wire are there for safety and balance. In AC current, two or three energized conductors can use each other to complete an electrical circuit.